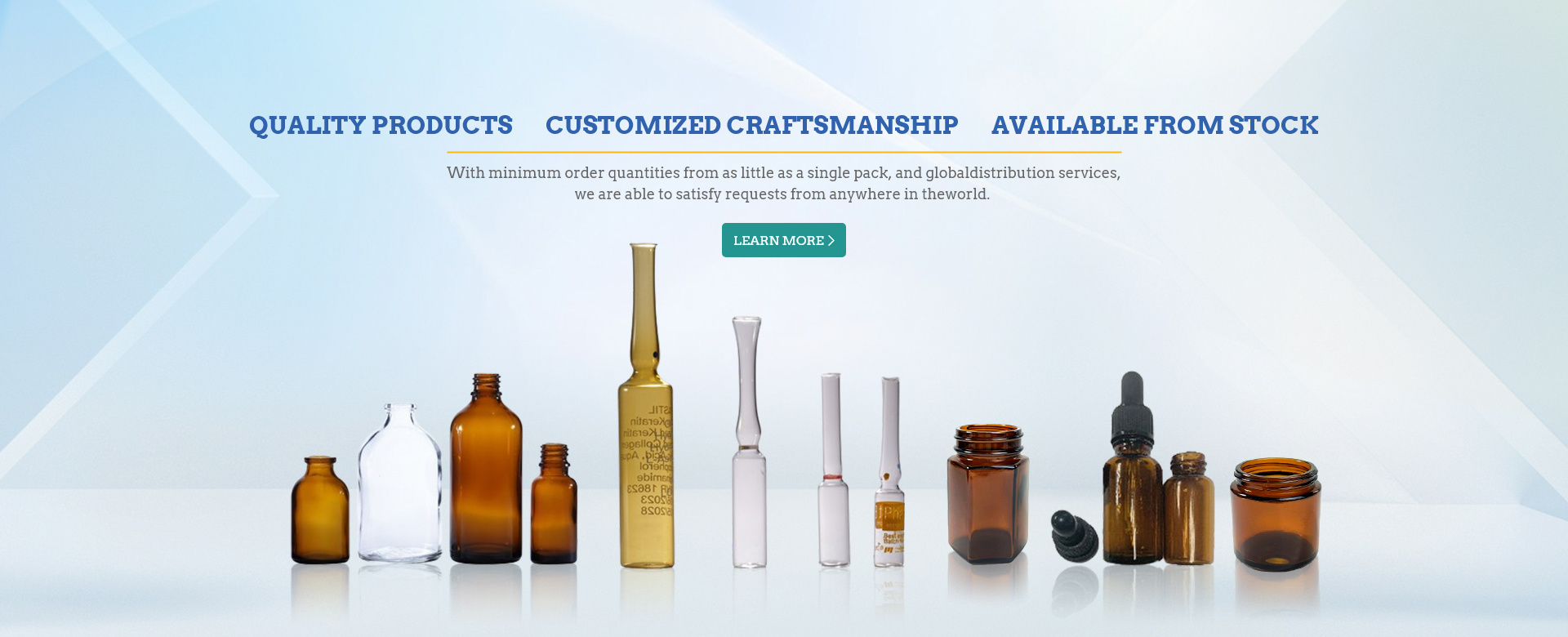

Tearable yellow aluminum-plastic cap for 20mm freeze-dried powder vials

Support customization and sample delivery!

Rubber stopper,aluminum plastic cap

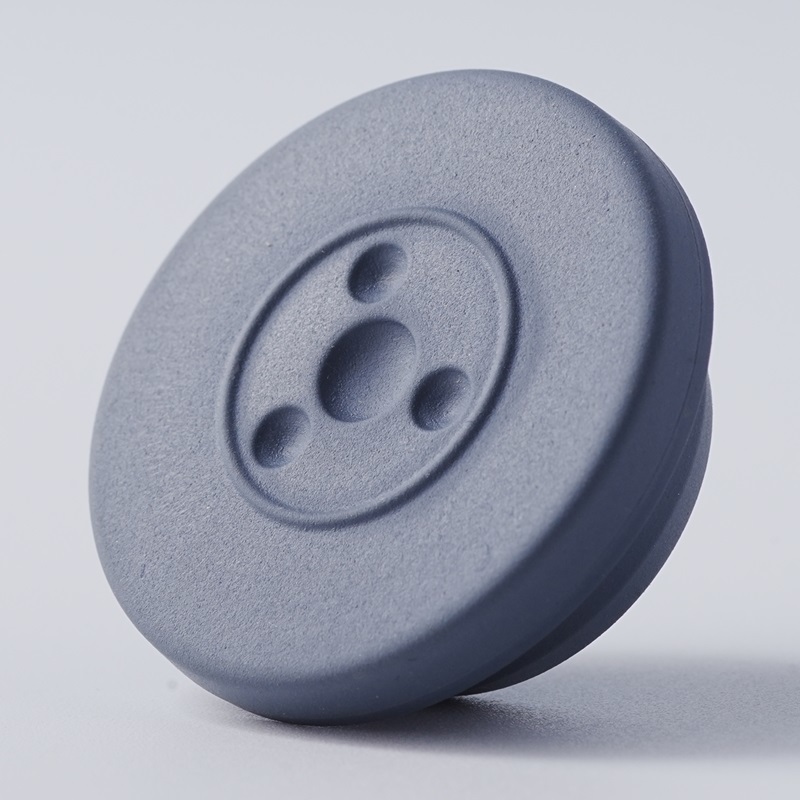

Butyl rubber stoppers for oral liquids

Butyl rubber stoppers for freeze-dried injections

Butyl rubber stoppers for powder and water injection

The combination of rubber stoppers and aluminum-plastic caps forms a common packaging used extensively in the fields of medicine, food, and chemicals. This combination offers the advantage of providing both excellent sealing and barrier properties, protecting products from air, oxygen, and moisture, and extending their shelf life.

MUNAN specializes in manufacturing safe and reliable pharmaceutical Butyl rubber stoppers and aluminium plastic caps, with more than 14 years of exporting experience.

Our company has advanced production equipment, professional technical personnel, comprehensive testing instruments, strict inspection standards, standardized production workshops and warehouses. We make every effort to build advanced hardware and software facilities, R&D system and central lab are according to international tech development direction and meet customers’ demand, and strive to be a world-class supplier of pharmaceutical packaging materials.

MUNAN has clean rooms of class 100,000 and part of class 1,000,000 cleanliness; Also equipped with more than 100 sets of various production equipment and laboratory testing instruments, which have reached the advanced level of automated production, and the annual production capacity of Butyl Rubber Plugs and Aluminium Plastic Caps can be up to 1,000,000,000 pieces.

Furthermore, Advanced production system combines independent & cooperative research & development.

Our main products have flip off caps, aluminum seals, rubber stoppers.

The color, dimensions and logo are all customizable. We can help you design the pharmaceutical packing, such as a complete set of glass vials, vial caps and rubber stoppers.

MUNAN company attach importance to product quality, have a good quality management system, production management fully in line with the requirements of GMP, we have ISO15378, CE, SFDA, ISO9001, ISO14001, FDA registration(DMF 034963), SGS, ROHS, REACH, PPAP, PAHS,etc.

We guarantee reliable products, competitive prices and comprehensive service. Our products have been exported to many countries, such as France, Germany, England, Greece, Turkey, Russia, Ukraine, Romania, Moldova, Egypt, South Africa, Nigeria, Israel, Iran, Saudi Arabia, Pakistan, Bangladesh, Thailand, Indonesia, Vietnam, Singapore, Malaysia, Australia, New Zealand, Korea, Canada, Mexico, Chile, Brazil, Argentina and other countries, gaining great popularity and having a good reputation from our customers.

We welcome customers from all over the world to visit and audit our factory, looking forward to cooperating with you.

Butyl rubber stoppers have good properties in terms of seasonality, heat resistance, chlorination resistance, and aging resistance.

The butyl rubber stopper is commonly used in tubular glass vials, moulded glass vials, and glass bottles for injection, and it is capped with aluminum or aluminum-plastic (flip-off) caps.

The advantage of butyl rubber stopper:

1.Good adhesion, ease of cleaning, non-hardening and non-stickness.

2.Butyl rubber plug with coated surface, the coating will prevent potential contamination between the rubber contact surface and the medicine, thereby expanding the applications for the stoppers.

3.The butyl rubber stopper has been continuously developed and tested by the company to have the right strength, Effectively reduce instances of leakage during needle insertion, extraction and inversion -hanging.

4.Environment protection, non toxic.

5.Complete specifications, wide range of uses.

6.Super sealing and anti vibration function.

7.These rubber material have high elasticity,insolation, waterproof and excellent,wear resistant, aging resistant, high/low temperature resistant, anti-corrosion, dust proof.

8.Superior service system, with professional technical personnel, to provide customers with supporting and personalized services at any time.

The advantage of Bromobutyl Rubber Stoppers:

1.These rubbers have excellent properties of durability, elasticity, and resilience.

2.Size and color: Customize

3.Compared to other rubbers, bromobutyl rubber is usually lower in extractables and has excellent resistance to water and oxygen penetration.

4.Lower hygroscopicity and is a better choice for freeze dried / lyophilization product applications. Higher stability and generally have a longer shelf life.

5.Faster cure rates and a shorter scorch or cure induction period (more efficient production)

requires lower levels of curatives and enables one to use a wider range of accelerators.

Advantages of Chlorobutyl Rubber:

1.Better resistance to heat and is the preferred stopper for high-heat sterilization techniques.

2.Efficiently produced without the use of stabilizers.

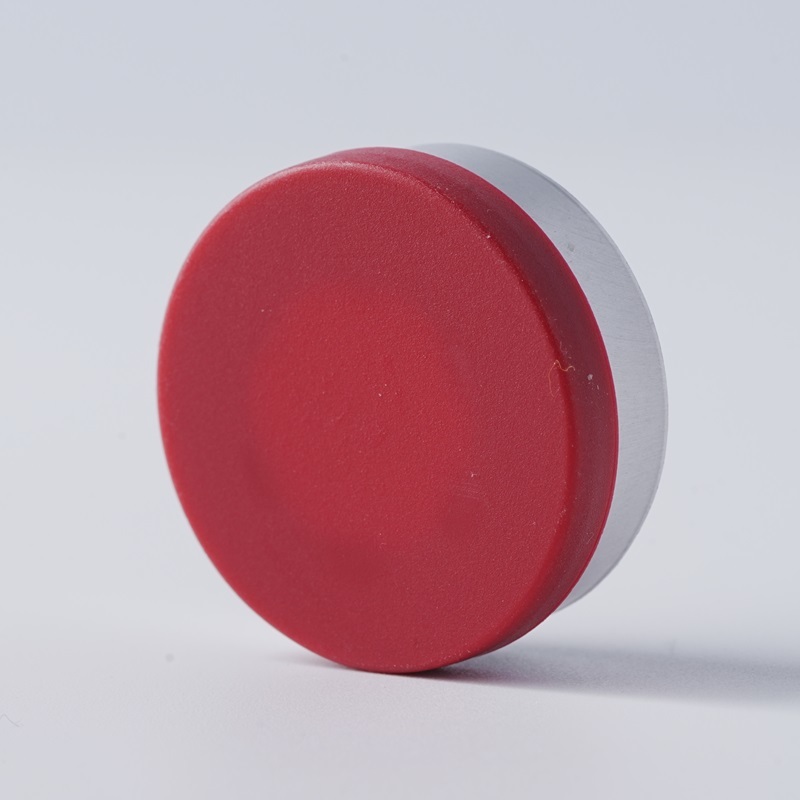

Advantages of aluminium-plastic caps:

1.Excellent material, rich in texture, every detail is highly sophisticated, sturdy and durable.

Flat section, various specifications, multiple materials, good sealing.

2.One cap for multiple uses, can meet a variety of specifications for bottles, to meet the various needs of customers.

Beautiful shape, flat cap, smooth feel, thickened design, not easy to deform, rigorous process, wear-resistant and durable, long use.

Usually assembly with rubber stopper used for sealing injection bottles or infusion bottles.

3.Assembling in 100000 class workshop , alse We have pure water producing workshop, we wash the aluminum parts by pure water and ultrasonic equipment then dry them, to avoid any oil and aluminum scarps.

4.Sterilization method: autoclave sterilizer, Ethylene Oxide(EO), we can supply sterile caps.

5.Temperature resistance of plastic part: 135 degree centigrade.

6.Temperature resistance of aluminum part coating: 180 degree centigrade.

7.Workshop: 100 class cleaning workshop meets the GMP standard.

Our Services:

1. Providing technical consultation.

2. Samples are free.

3. Special packaging according to request.

4. Providing related qualification documents.

5. We could customize various flip off cap and tear off cap with your brand logo according to your requirements.

6. Solving customer's complaints in time .

7. We make full inspection during the production, and we also make sampling test before delivery.

8. Pilfer-proof feature ensures the completeness of the product. 5 sizes available including 13mm, 22mm, and 34mm. All products are manufactured in class 100,000 clean room. Also, we are certificated by FSSC22000, HACCP, and many others.

| Name | Rubber stoppers, Aluminium plastic cap | Brand | MUNAN |

| Logo | Customized Logo Acceptable | Payment Method | L/C, D/A, D/P, T/T, Western Union, MoneyGram, ESCROW, e-Credit Line2 |

| Color | Custom Color | Nature of business | Makers |

| Material | Low borosilicate glass / Neutral borosilicate glass / High borosilicate glass | Seller's Name | JINAN MUNAN PHARM GLASS CO., LTD |

| Certification | ISO15378, CE, SFDA, ISO9001, ISO14001, FDA registration(DMF 034963), SGS, ROHS, REACH, PPAP, PAHS,etc. | Place of Origin | Jinan, China |

| Application | Closures for Injection bottles, infusion bottles, Oral fluid bottles, etc. | Annual Turnover | $20 million |

| Sizes | Customizable | Feature | Good sealing |

| Packaging | PE Bag and Carton or as Per Your Request | Lead time (days) | 30 days |

| MOQ | 50000PCS | Supply Ability | 10000000 Piece/Pieces per Month |

| OEM / ODM | Surpport | Surpport | Free |

Expand more

FAQ

Latest news