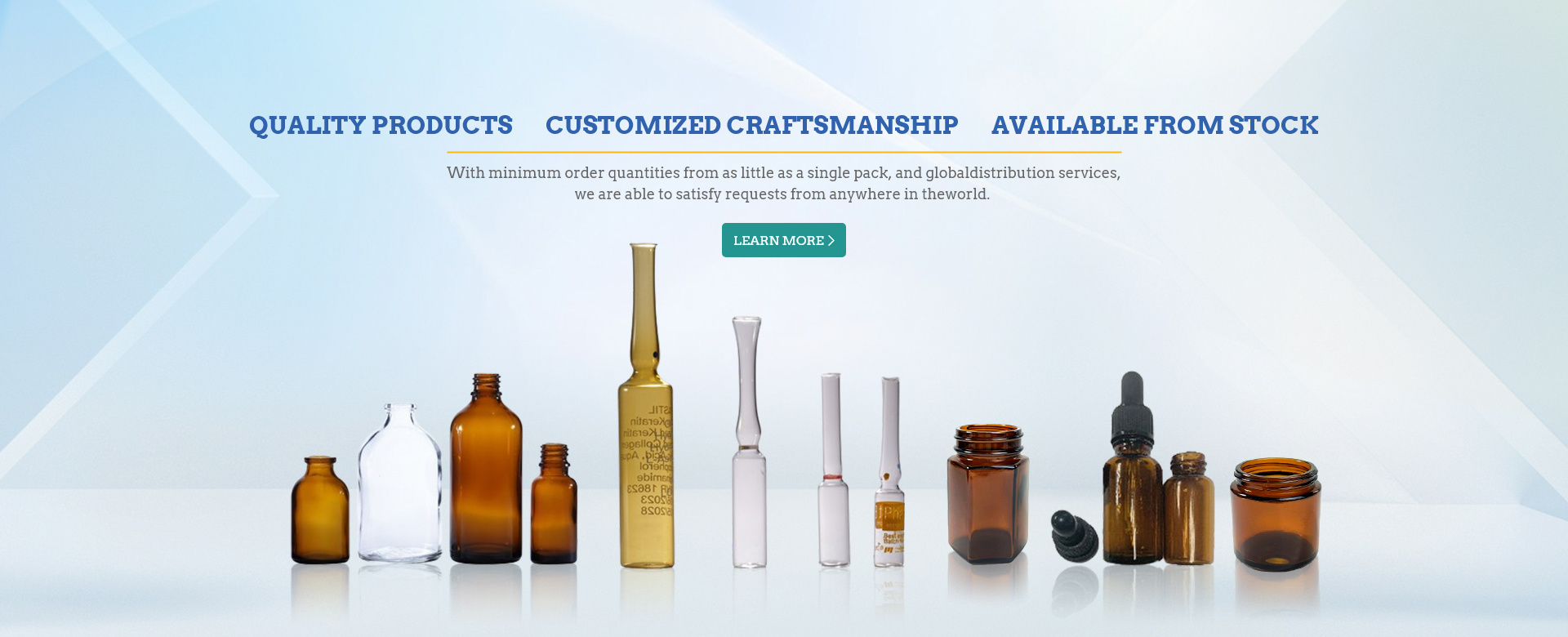

Support customization and sample delivery!

glass cartridge, pre filled syringes and accessories

MUNAN is a company capable of producing prefilled glass syringes, Cassette bottles, and accessories (including inner packaging materials for prefilling and cartridges, such as sealing elastomers, push rods, needle shields, and gaskets). These products are widely used in the medical field.

Product line:

1. MUNAN focuses on the production of prefilled glass syringes, cartridges, and accessories. These products are mainly used in the medical and pharmaceutical industries to ensure the safety and effectiveness of drug storage and use.

2. Certification and compliance: MUNAN's factories hold multiple international certifications such as ISO15378, ISO 13485, GMP certificate, ISO14001, OHSAS18001 and ISO 9001 to ensure that their production and quality control processes meet international standards. In addition, MUNAN has obtained the EU CE certification, and Obtained the U.S. FDA DMF number 027355, 026095, and the Canada DMF number, e200827. This indicates that its products meet international safety and quality standards.

Facilities: It has a standardized workshop warehouse of 30,000 square meters that meets GMP standards, and more than 3,000 square meters of Grade A, B, and C purification workshops. These facilities ensure the cleanliness and sterile production environment of the products.

4. Technical team: MUNAN has more than 50 technical personnel, with a complete R&D and design team and strong technical strength. This ensures that MUNAN remains a leader in technology and product innovation.

5. Quality Control System: MUNAN focuses on product quality control and has a strict quality inspection and control process from the procurement of raw materials, introduction and maintenance of equipment, training of personnel skills to the delivery of finished products. This ensures the quality and safety of each batch of products. MUNAN Cartridges are manufactured on state-of-the-art fully automatic production line with highly stable and validated processes Permanent process optimization through Six Sigma principles, along with ongoing professional training for employees, helps uphold quality of the highest levels. The product is 100% camera inspection, and the A-level is equipped with a 24-hour online dust particle and auto-matic planktonic monitoring system to ensure the stable appearance and quality of the product and improve the quality of the product.

6. Market position: MUNAN has a certain position in the international market, with its products exported to more than 50 countries and regions. With its high-quality products and good reputation, MUNAN has won the trust and support of customers.

MUNAN has introduced advanced equipment such as new fully automatic production lines, intelligent automatic material handling and punching machines, servo trimming machines, fully automatic inspection equipment, pre-washers, and fully automatic packaging equipment. The products are automatically produced with online detection of appearance, foreign objects, and other factors.

It is equipped with a standard laboratory that possesses various analysis instruments such as ion chromatograph (C), gas chromatography-mass spectrometer (GC-MS), liquid chromatography (HPLC), inductively coupled plasma mass spectrometer (ICP-MS), scanning electron microscopy instrument, particle size analyzer, attached Liye transform infrared spectrometer, high performance liquid chromatography, Mooney viscometer, total organic carbon (TOC) analyzer, etc., enabling various inspections of raw materials, semi-finished products, and finished products and testing of physical and chemical properties. The company has a complete and rigorous production management system and talent cultivation mechanism, with a particular emphasis on product technology research and development. It has mature technical experience in glass syringe water resistance control, cartridge wear resistance and chemical resistance, syringe sealing performance, sliding properties, cone sealing performance, stress, residual liquid volume, capacity tolerance, welding strength, and appearance.

We will continue to provide high-quality syringes at competitive prices.

After 14 years of unremitting efforts, MUNAN has now developed into a technology-leading company with a complete range of products that specializes in the research, development, manufacturing, and sales of direct contact packaging for various injection drugs.

It has an annual production capacity of 8 million prefilled syringes, 10 million cartridges, and 20 million related accessories. It is a quality supplier to dozens of domestic pharmaceutical companies and has exported to more than 50 countries and regions, receiving unanimous recognition and praise from customers worldwide!

The manufacturing process strictly follows GMP standard control and complies with the specifications of YBB, EP, USP, and JP according to product types.

The glass prefilled syringes is a disposable injection device including glass barrel, plunger, plunger rod, needle and cap, that is already filled with the single dose of medication the patient needs to injec. By avoiding filling the syringe from a vial, the process is faster, easier and more accurate. Be widely used in Vaccines, Anti-coagulants, Anti-inflammatory agents, Hormone therapies, Cancer therapies, Pain relievers. The glass prefilled syringes are made of type I neutral borosilicate glass. Whether for biologics, vaccines, insulin, the prefilled glass syringe is the effective, safety, reliable and sustainable packaging solution for you. The glass prefilled syringes are sterilized and packed into a nest box and Tyvek bag. You can use it directly when you get it. The proportion of sales of therapeutic injectable drugs is currently increasing, and the application of pre-filled seals has been broadened to include many of the following areas:

Vaccines, Anti-coagulants, Anti-infectives, Anti-inflammatory agents, Haematological agents, Multiple sclerosis therapies, Hormone therapies, Obstetric agents, Cancer therapies, Pain relievers.

We offer our customers integrity sealing solutions with the highest quality for their syringe systems. We are specialized to supply Cassette bottles, Rubber plunger stoppers, Rubber-lined aluminum seals, and Needle shield for prefilled syringe.

Sterilization Process:

To use ethylene oxide (EO) for sterilization in the equipment from local, which completely meet the requirements of sterilization.

Before filling medicine, the cleaning, silication, and drying sterilization of non-sterile pre-filled glass syringes are required; this process is carried out in a pharmaceutical or medical device factory.

Our most accurate production and gentle cartridge-handlig to date facilitates tight dimensions and premium surface quality that reliably ensures superior container processing, device compatibility and reliable performance at point of use.

Outstanding processability:

Tight geometric tolerances due to 100% camera inspection for tubing and containers.

Low cosmetic defect level owing to cosmetic defect detection during tube drawing and avoidance of glass-to-glass contact during container forming.

Reliable product at point of use:

Accurate dosing.

Break resistant.

Low residual' volumes.

Product Features:

1. Accessories of glass prefilled syringes have good compatibility with drugs.

2. Heat resistant and airtight. The prefilled syringe has good sealing function and the drug could be stored for long time.

3. Medical grade and sterile packaged. After sterilization then packed the syringes into a nested box can be provided.

4. All product details can be customized. Support Logo-Printing and Custom logo.

5. The material and construction is resistant to breakage from shock and sudden temperature changes.

6. It is annealed and tested until free of internal strain, to withstand repeated washing with hot water.

7. Plunger is individually ground and fitted to barrel for smooth movement with no back flow.

8. The syringe can be clearly marked with graduations. The graduations are permanently fused for lifetime legibility.

9. It has good characteristics such as water resistance, freeze-thaw resistance, acid resistance, alkali resistance, and thermal shock resistance.

10. It has good characteristics of chemical stability and shock resistance. It can be widely used in various types of liquid injection, power injection, and freeze-drying medicine packaging.

11. Easy to use/Reduce pollution/Accurate dosage.

12. Can be sterilized up to 160°C / 320°F.

13. Avoid secondary infection. Preventing cross-infection or secondary contamination during injections.

14. Preventing medication errors. The name of the drug can be indicated on the injection container, which makes errors less likely to occur in the clinic.

15. Easy to operate. Saves half the clinical time of Bian, especially for emergency care.

MUNAN cartridges have excellent device compatibility and reliability, and due to their extremely precise drug dosage distribution characteristics, are commonly used for packaging insulin and anesthetic products, providing users with a safer, simpler, and more stable packaging format.

Cartridge bottle, also known as pen-type syringe glass sleeve.

The cartridges are made of transparent, 5.0 neutral borosilicate glass, with a water resistance rating of Class 1; low- and high-borosilicate cartridges are also available.

We have the first fully automatic production line for cassette bottles in China, which minimises the risk of potential contamination caused by manual assembly; GMP-level quality control of pharmaceutical products and the production of the whole process of class 10,0000 clean room, so that the products are safe and secure.

MUNAN cassette bottles - From Standardized to Customized

Quality Options

A broad range of container geometries, quality levels and controlled surface chemistry enable us to tailor the primary packaging solution to your specific needs. All MUNAN Cartridges are manufactured and packed in environmentally controlled areas certified Aa ISO 9001 and ISO 15378 and comply with PH.Eur., USP and JP international standards.

Cassette bottles Standardized quality level according to ISO.

Our Manufacturing Process

Clear Commitment to Quality

MUNAN Cartridges are manufactured on state-of-the-art production lines with highly stable and validated processes Permanent process optimization through Six Sigma principles, along with ongoing professional training for employees, helps uphold quality of the highest levels.

Throughout the process, cartridge-handling is continuously optimized to decrease glass-to-glass contact, thereby resulting in cartridges with increasing in mechanical strength and exceptional cosmetic quality.

Product Advantage:

1.Thickened glass, various specifications, recycling, healthy material, anti-corrosion function.

2.Optional screen printing, labelling, hot stamping, silver hot stamping, spraying and other processes can be processed.

Matching aluminium caps, gaskets, pistons, push rods and caps are available.

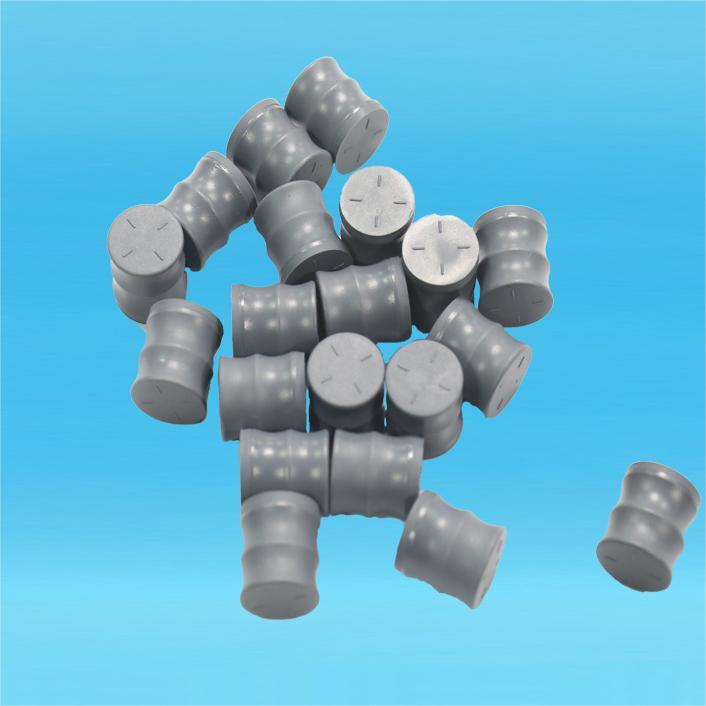

Medicinal rubber plungers are widely used as primary packaging for various types of medicines. However, some relatively high-end packaging products such as prefilled syringes require rubber plunger have higher requirements for compatibility. MUNAN supplied products will make sure that our rubber components for prefilled syringes will meet all necessary functions.

The stopper (plunger or bung) is made of rubber that can be of different qualities and types. Today two classes of rubber are mainly used for prefilled syringes: one is chlorobutyl rubber, the other made of bromobutyl rubber.

Plunger moulded with high precision, uniform size, no burr, good sealing, no leakage, easy to push and pull.

COP/COC production and assembly line:

injection molding in C-level environment, pretreatment is transported into B+A environment for

assembly (honeycomb box), testing, packaging.

The product is 100% tested, and the A-level is equipped with a 24-hour online dust particle and auto-matic planktonic monitoring system to ensure the stable appearance and quality of the product and improve the quality of the product. For RTS (no-cleaning to be extinguished), RTU (no-cleaning and non-extinguishing) products.

The cap is located at the opposite end of the cartridge from the rubber plunger, and it is contained into an aluminum metal ring. The lined rubber is typically made of the same kind as the plunger rubber (usually bromobutyl rubber).

Protecting the needle from external forces is another important aspect when it comes to injectables. Both our soft and rigid needle shield that ensure the needle will not damaged during production, filling, and distribution.

Pre-filled rubber gaskets:

The designed annual production capacity is billion pieces The automatic vulcanization process

(plate vulcanization, trimming pre-wash, light inspection, and automatic loading and unloading system);cleaning machine imported from Germany (meet the requirements of pharmaceutical Asnpu! in the United States, Europe, and China). Packaging in Class A and 1 00% light inspection( 24-hour online dust particle and planktonic bacteria monitoring system Class A) to ensure stable stability of product appear-ance and quality.

Plunger rod:

Colour and material of the Plunger rod can be customised.

MUNAN Pre-filled packaging material production line:

The workshop is designed in accordance with GMP standardization, pue the production line has

a pauuejd area 1200 square meters, projects include: aluminum des pue lined seal for cartridges, seypally-aud rubber gaskets, pue COC/COP products.

Company Advantage:

1. high standard of cleanliness and fully automated equipment. fully automated production and packaging under class 100,000 clean area, which helps to reduce microbial contamination and reduce drug dosage errors.

2.Superior service system, with professional technicians, ready to provide customers with supporting and personalised services;

3. Supplying well-known pharmaceutical manufacturers at home and abroad.

4. Produced with high quality raw materials.

5. Non-toxic, non-pyrogenic, Sterilised by EO gas or steam.

In addition, the company supports surface colour printing and customized services, Glass syringes that meet childproofing features are also available.

Following options upon request:

Customized length and diameter

Reduced (tighter) tolerances

Customizable cosmetic quality level

Printing / graduation / ring

Double chamber geometry with bypass

Mechanical strengthening

| Name | Cassette bottles,pre filled syringes and accessories | Brand | MUNAN |

| Logo | Customized Logo Acceptable | Payment Method | L/C, D/A, D/P, T/T, Western Union, MoneyGram, ESCROW, e-Credit Line2 |

| Color | Clear / Amber / Customized | Nature of business | Manufacturer |

| Material | Low / High / Medium borosilicate glass | Seller's Name | JINAN MUNAN PHARM GLASS CO., LTD |

| Certification | ISO15378, ISO 13485, GMP certificate, ISO14001, OHSAS18001 and ISO 9001, the EU CE certification, the U.S. FDA DMF number 027355, 026095, and the Canada DMF number, e200827 | Place of Origin | Jinan, China |

| Application | Pet medicine, medical cosmetology, potting glue, cbd, cartridge filling, biological products | Annual Turnover | $1 million |

| Sizes | 0.5ml/1ml/1.5ml/2.25ml/3mI/5ml/10ml or Can be customized | Feature | Good compatibility with drugs, Good sealing, resistant to damage and corrosion, long service life. |

| Packaging | Nest box + Tyvek bag + Strong Carton or PP tray box+carton, Medical grade and sterile packaged | Lead time (days) | 30 days |

| MOQ | 10000PCS | Supply Ability | 5000000 Piece/Pieces per Month |

| OEM / ODM | Surpport | Surpport | Free |

| Sterilization | Sterilized by EO gas | Surface Handling | Acid Etch or other |

Expand more

FAQ

Latest news